Extreme Ultraviolet Lithography (EUV) Mask Blanks

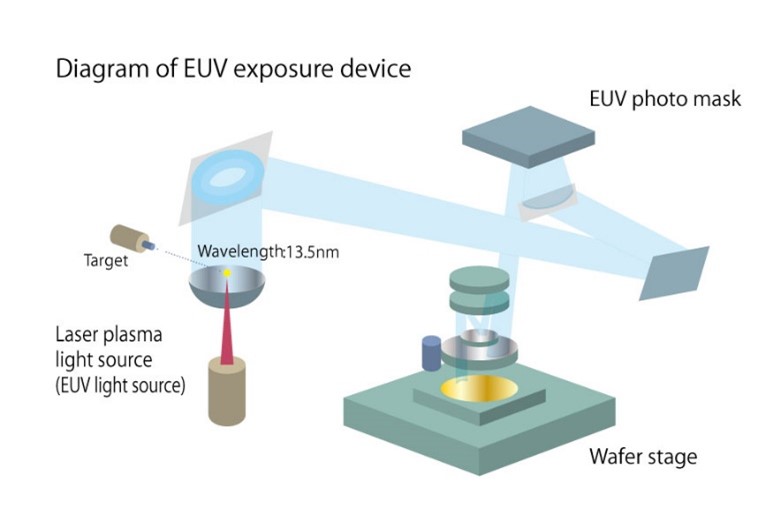

EUVL mask blanks are a low-thermal expansion glass substrate with various optical coating films on its surface. An EUV photomask comprises a semiconductor chip circuitry pattern formed onto the surface of an EUVL mask blank, which is then transferred onto a silicon wafer to create a semiconductor chip. As semiconductor circuits become finer, the requirements for EUVL mask blanks are rising, demanding minimal defects and extremely high flatness.

In recent years, the EUV process has been increasingly adopted in semiconductor production, not only for logic devices but also for DRAM and other memory devices. This trend has led to a significant increase in demand for EUVL mask blanks. To meet this growing demand and support the next generations of semiconductors, AGC is expanding its production capacity.

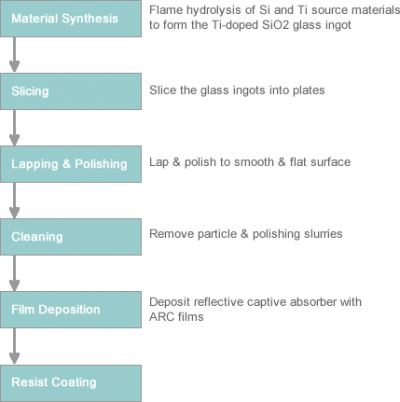

AGC began R&D on photomask blanks for semiconductor production using EUV lithography technology in 2003. By 2017, AGC started production of EUVL mask blanks, leveraging its proprietary technologies in glass materials, glass processing, and coating. As the world’s only EUVL mask blank manufacturer capable of handling all processes from glass materials to coating, AGC will continue to make necessary investments in response to market needs. In July 2020, AGC decided on a major expansion project, including building expansion at Group company AGC Electronics, where production started in January 2022.

Under its AGC plus 2.0 management policy, the AGC Group has positioned the Electronics business as a strategic business. AGC will continue to make aggressive capital investments in the EUVL mask blank business, aiming for sales of more than 40 billion yen by 2025 and contributing to the advancement of the semiconductor industry.

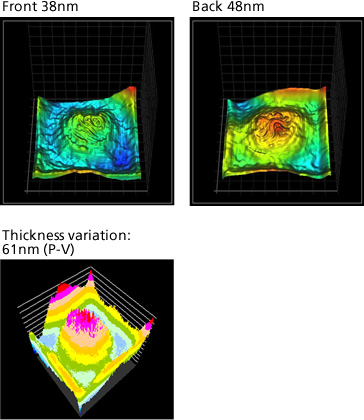

Flatness and Defectivity

>50nm flatness of both sides with low defectivity

Manufacturing Process

Contact us to Request Product Literature and More Information

Please email ea.customerservice@agc.com